Automate the mundane, focus on what matters

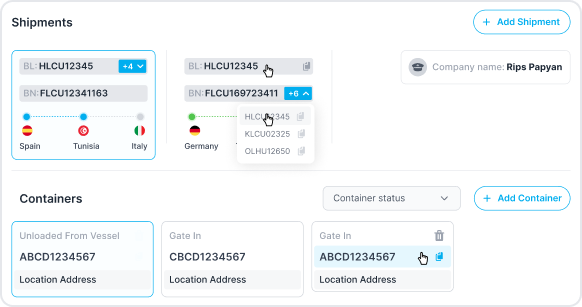

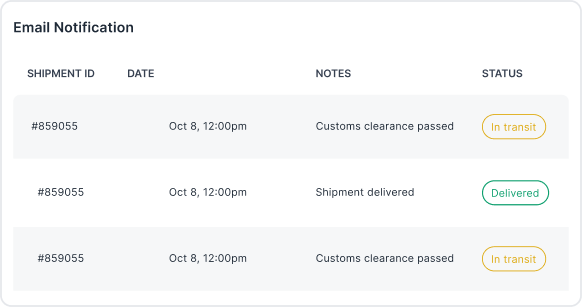

Stay ahead with discharge and transshipment alerts

Receive instant alerts for container discharges and missed transshipments, empowering you to act swiftly against any disruptions. With Dockflow’s no-code automation builder, you can go beyond notifications and fully automate your entire workflow. Customize and streamline every step of your logistics operations, ensuring your team stays proactive, responsive, and always a step ahead.

Never miss an ETA update

Dockflow’s automation tools ensure you’re always up-to-date with real-time ETA notifications. This minimizes delays and keeps your logistics operations running smoothly without manual intervention.

Effortless data sharing with partners

Automatically share critical shipment data with specific partners through Dockflow’s platform. Our platform enhances collaboration and ensures that everyone in your supply chain is informed and aligned without the need for repetitive tasks.

Automate logistics operations effortlessly

Centralize your data

Dockflow brings all your logistics data into one platform, enabling seamless access and decision-making without data silos.

Enable smarter tracking

Track every shipment in one place with Dockflow’s logistics enablement tools, ensuring full visibility and control over operations.

Frequently asked questions about automation

What is logistics automation, and why is it important?

Logistics automation refers to the use of technology and automated systems to streamline and optimize logistics processes. These include shipment tracking, inventory management, and communication. It eliminates manual tasks, reduces errors, and ensures faster, more efficient operations.

Automation is important because it enhances visibility, improves decision-making, and reduces costs. This enables businesses to meet growing demands and maintain a competitive edge in the supply chain.

How does automation improve supply chain efficiency?

Automation streamlines processes, eliminates manual errors, and ensures real-time visibility into supply chain operations. It enables proactive decision-making through predictive insights and tailored alerts. Businesses benefit from smoother workflows, reduced delays, and optimized resource use, creating a more efficient supply chain.

How can Dockflow’s automation platform reduce manual tasks?

Dockflow automates repetitive logistics processes, such as tracking shipments, sending alerts, and updating shipment milestones. It consolidates data from multiple sources into a single platform, eliminating the need for manual data entry.

Customizable workflows and notifications ensure that routine tasks are handled automatically, freeing up teams to focus on strategic operations.

What types of workflows can I automate with Dockflow?

Dockflow allows you to automate a wide range of logistics workflows, including:

- Shipment Tracking: Automatically monitor container movements and updates.

- Alerts and Notifications: Set up tailored alerts for milestones, delays, and threshold breaches.

- Demurrage Management: Track free time limits and receive proactive notifications to avoid penalties.

- Document Sharing: Automate the distribution of critical shipment documents to stakeholders.

- Temperature and Humidity Monitoring: Receive automated updates for sensitive cargo conditions.

These automated workflows help streamline logistics operations, reduce manual effort, and improve efficiency.

Can I customize alerts based on specific milestones or thresholds?

Yes, Dockflow allows you to fully customize alerts based on specific milestones or thresholds. You can set notifications for events such as container discharges, delays, or threshold breaches for temperature and humidity levels.

This flexibility ensures you receive the most relevant updates, enabling proactive decision-making and smoother operations.

Can alerts be sent to multiple team members or partners?

Yes, Dockflow supports sending alerts to multiple team members or partners. Notifications can be configured to reach the right stakeholders, ensuring everyone stays informed about key milestones, delays, or deviations.

This feature enhances collaboration and keeps operations aligned across the supply chain.

How quickly does Dockflow send notifications when issues arise?

Dockflow sends notifications as soon as critical events or deviations are detected. For key shipment events such as vessel arrival, discharge, or environmental threshold breaches, alerts are triggered and delivered promptly to help teams take immediate action and maintain control over operations.

Does Dockflow offer daily or summary alerts for logistics updates?

Yes, Dockflow provides daily and summary alerts to keep you updated on key logistics activities. These summaries consolidate information such as shipment milestones, delays, and critical updates, offering a clear overview of your operations. This ensures you stay informed without needing to monitor every detail in real-time.

Does Dockflow integrate with existing freight management systems?

Yes, you can customize Dockflow to provide daily or summary alerts tailored to your needs. These alerts consolidate key logistics updates, including shipment milestones, delays, and critical events. This ensures you stay informed with a clear overview of your operations.

How can automated logistics improve supply chain management?

Automated logistics systems improve supply chain management by streamlining processes, reducing manual errors, and enhancing visibility. These systems provide real-time tracking, automate routine tasks, and enable faster decision-making through tailored alerts and predictive analytics.

By optimizing resource allocation and minimizing delays, automated logistics systems create more efficient and reliable supply chains.

What are the advantages of using automated logistics systems for shipment tracking?

Automated logistics systems save time by eliminating the need for manual updates and providing real-time tracking data. This allows businesses to make informed decisions quickly, addressing potential disruptions before they escalate. By automating routine tracking tasks, teams can focus on more critical and demanding issues, improving overall efficiency and operational performance.

How does automation reduce errors in logistics operations?

Automation reduces errors in logistics operations by standardizing processes and eliminating manual data entry. Automated systems consolidate data from multiple sources and ensure accuracy in tracking, documentation, and communication.

This minimizes miscommunication, prevents delays, and improves the reliability of logistics workflows, leading to smoother and more efficient operations.

How does automated logistics improve collaboration between partners?

Automated logistics improves collaboration by providing a centralized platform where all partners can access real-time data and updates. This transparency ensures everyone stays informed, reduces miscommunication, and enables seamless coordination. Centralized systems streamline communication, making it easier to align workflows and achieve shared logistics goals.

Can Dockflow automate specific processes, such as demurrage tracking or temperature monitoring?

Automated logistics improves collaboration by providing a shared platform where all partners can access real-time data and updates. This shared access ensures transparency, reduces miscommunication, and keeps everyone aligned on shipment statuses and key milestones.

By enabling seamless coordination, automated logistics helps partners work more efficiently and avoid delays in operations.

Does Dockflow provide automation solutions for reducing operational costs?

Yes, Dockflow provides automation solutions that significantly reduce operational costs. Automated workflows for tracking shipments, managing demurrage timelines, and monitoring free time limits help prevent unnecessary fees and delays.

Tailored alerts notify teams of potential issues, such as threshold breaches or missed milestones, allowing for quick interventions.

Dockflow eliminates repetitive manual tasks and streamlines logistics processes, reducing inefficiencies, optimizing resource use, and driving cost savings across the supply chain.

What makes Dockflow an ideal choice for implementing automated logistics systems in supply chain operations?

Dockflow is an ideal choice because it combines advanced automation tools with real-time visibility and customizable workflows. The platform simplifies complex logistics tasks such as shipment tracking, alert management, and document sharing.

Seamless integrations with existing systems ensure smooth operations, while predictive analytics and tailored notifications enhance decision-making.

Dockflow’s user-friendly interface and no-code automation builder make it accessible for teams, enabling efficient and scalable supply chain management.

Unlock new possibilities for your business with Dockflow