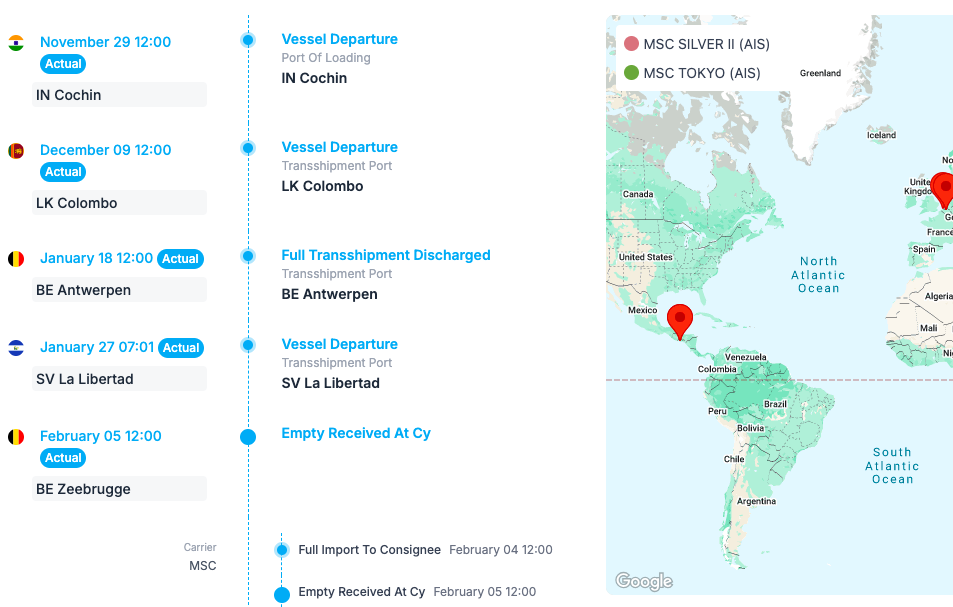

Stay informed on container ETA and unloading

Integrated warehouse data insights

Connect Dockflow with your warehouse management systems to consolidate data, enabling more accurate inventory and storage planning.

Temperature monitoring for sensitive goods

Track temperature-controlled shipments from container discharge to warehouse storage, ensuring compliance with sensitive cargo requirements.

Seamless coordination with transportation teams

Dockflow bridges communication gaps between warehouses and transportation teams, streamlining the flow of goods into and out of facilities.

Optimized space utilization

Leverage Dockflow’s insights to improve warehouse layout planning and maximize storage efficiency for incoming goods.

Real-Time Terminal Data for Enhanced Precision

Gain faster, more accurate updates directly from terminal data sources. Dockflow delivers real-time insights, ensuring warehouses and trucking teams are always one step ahead in coordinating operations from terminal to warehouse.

Powering the world's supply chains

Why Dockflow?

Dockflow provides tailored discharge alerts, real-time container tracking, and seamless logistics visibility. Our software empowers warehouses to streamline operations, minimize delays, and enhance strategic choices with precise, actionable insights.

Benefits

Maximize warehouse efficiency with Dockflow

Our customizable alerts system provides real-time status updates, ensuring you’re the first to know when your container is discharged.

Seamless supply chain coordination

Dockflow grants smooth logistics coordination by connecting warehouse data with real-time shipment updates.

Reduced manual tracking efforts

Eliminate repetitive tracking tasks –and errors– with Dockflow’s automated container monitoring and notification system.

Enhanced operational efficiency

Optimize warehouse operations with precise insights that improve decision-making and resource allocation.

Forwarders going digital with Dockflow

Frequently asked questions about warehousing

How can technologies like Dockflow improve warehouse operations?

Dockflow enhances warehouse operations by providing real-time visibility into incoming shipments, eliminating the need for manual checks. With proactive notifications, warehouse teams can efficiently plan and allocate resources, ensuring smooth workflows.

By knowing exactly what’s arriving and when, Dockflow empowers better decision-making, saves time, and optimizes overall warehouse efficiency.

What are the key challenges in managing inventory in warehouses?

Keeping track of incoming shipments manually is time-consuming and prone to errors, impacting efficiency. Dockflow addresses these challenges by providing real-time shipment visibility, eliminating the need for manual checks. This ensures smooth operations, better resource planning, and improved overall efficiency for warehouse management.

How does data integration enhance warehouse efficiency?

Data integration enhances warehouse efficiency by consolidating information from various sources, such as shipping schedules, container tracking, and inventory systems, into a single platform.

This real-time visibility enables better planning, reduces manual tasks, and minimizes errors. With Dockflow’s seamless data integration, warehouses can optimize workflows, allocate resources effectively, and ensure smoother operations.

What is SAP and WMS?

SAP (Systems Applications and Products) is an enterprise resource planning (ERP) software that helps businesses manage various processes, including finance, logistics, supply chain, and customer relationships, through integrated systems.

WMS (Warehouse Management System) is specialized software designed to optimize warehouse operations, including inventory tracking, space utilization, order fulfillment, and coordination of inbound and outbound logistics.

How does Dockflow connect with existing warehouse management systems (WMS)?

Yes, Dockflow integrates seamlessly with your existing systems through our API, such as freight management, ERP, or terminal tracking tools. This integration ensures a smooth flow of data, enabling real-time monitoring of demurrage timelines and free time limits.

By connecting your logistics ecosystem, Dockflow helps you proactively manage demurrage and reduce unnecessary fees.

What role does temperature tracking play in warehousing for sensitive goods?

Temperature tracking is vital for maintaining the quality, safety, and compliance of sensitive goods stored in warehouses. It ensures that perishable or temperature-sensitive items remain within required conditions, reducing waste and costs while protecting customer satisfaction.

Additionally, temperature tracking provides transparency throughout the supply chain, allowing you to identify and address issues during transportation or storage, ensuring accountability when things go wrong.

How does Dockflow streamline communication between warehouses and transportation teams?

Dockflow provides a centralized platform where both warehouses and transportation teams can access real-time updates and notifications tailored to their needs. For example, when a container is discharged, the transportation team is notified to pick it up, while the warehouse can prepare for the incoming shipment. This shared visibility and coordination ensure smooth handovers, reduce delays, and streamline operations effectively.

What types of data insights does Dockflow provide for inventory and storage planning?

Dockflow delivers real-time data insights such as container arrival times, shipment statuses, and temperature or humidity conditions for sensitive goods. These insights help warehouses optimize space utilization, prepare for incoming inventory, and ensure proper storage conditions. With Dockflow, businesses can make data-driven decisions to improve efficiency and maintain inventory accuracy.