Empowering data quality with AI algorithms

AI-powered anomaly detection for error-free operations

Dockflow’s AI-powered algorithms identify and flag data anomalies in real-time, reducing the impact of manual errors and unreliable sources. By detecting inconsistencies across logistics systems, Dockflow ensures clean, actionable data, empowering teams to focus on decision-making without worrying about inaccuracies or disruptions.

Unifying insights from comprehensive data sources

Dockflow consolidates data from multiple sources, including AIS, terminals, IoT sensors, and freight management systems, into one unified platform. This integration eliminates data silos and provides a complete, real-time view of your logistics operations, enabling seamless collaboration and better decision-making across your supply chain.

Ensuring accuracy and completeness for confident decision-making

Dockflow combines advanced data quality algorithms and AI to filter out bad data, ensuring every insight is reliable and actionable. With accurate and complete data at your fingertips, you can make informed, confident decisions to optimize operations, improve efficiency, and achieve strategic goals.

Achieve precision with reliable, high-fidelity data

Eliminate uncertainty with accurate data insights

Dockflow’s high-fidelity data provides a clear and precise picture of your logistics operations, reducing guesswork. With accurate insights at every stage, you can confidently address challenges and optimize decision-making processes.

Foster consistency across your supply chain

Reliable data ensures smooth and consistent operations throughout your supply chain. It reduces variability, enhances collaboration between partners, and enables efficiency and alignment across all logistics activities.

Frequently asked questions

How do we import data into the platform?

Dockflow offers multiple import methods tailored to your operational scale. For one-off shipments or quick uploads, users can manually enter data directly within the platform. For bulk imports across multiple trade flows, Dockflow provides a structured Excel template where you can input key shipment identifiers such as internal reference, container number, booking reference, or bill of lading.

Once submitted, Dockflow intelligently enriches the dataset by retrieving additional shipment events and updates from verified sources. For organizations seeking full automation, Dockflow’s API allows seamless system-to-system integration, enabling continuous data transfer between your internal tools and Dockflow with minimal manual input.

Can we export the data to Excel?

Yes. Dockflow supports full data export in Excel format. All shipment details, event histories, and container insights available within the platform can be downloaded and structured into Excel for further analysis, reporting, or offline recordkeeping.

This ensures data accessibility for both operational teams and external stakeholders while preserving Dockflow’s standards for data integrity.

How does Dockflow use AI to detect data anomalies in real time?

Dockflow leverages proprietary AI models to continuously audit inbound data streams for inconsistencies, anomalies, or missing information. These algorithms monitor temporal, spatial, and behavioral patterns across vessel movements, container updates, terminal events, and carrier feeds.

When a deviation occurs, such as duplicated timestamps, early port calls, or gaps in milestone progression, the system flags it instantly. This prevents corrupted data from entering operational flows and ensures frontline teams are reacting to verified, context-aware information rather than noise.

How does Dockflow maintain data integrity across complex global logistics operations?

Dockflow applies a layered validation framework that cross-references each data point across multiple trusted sources before it is surfaced to the user. For example, an arrival event is only confirmed once validated through AIS signals, terminal feeds, and carrier updates.

If discrepancies arise, Dockflow prioritizes the most trusted source and suppresses conflicting data. This integrity-first approach scales seamlessly across multinational operations, where shipments may transition through multiple carriers, ports, or tracking systems.

Which data sources are integrated into Dockflow’s platform?

Dockflow unifies tracking data from AIS vessel tracking, satellite signals, GPS, port terminals, carrier EDI feeds, IoT container sensors, and freight management systems. These data streams are structured into a single supply chain visibility platform, delivering a real time view of location, conditions, and performance.

This multi-source integration allows Dockflow to replace fragmented logistics workflows with a centralized, decision-ready system that works across every trade lane and shipping line.

Can Dockflow identify and filter out inaccurate or duplicate data?

Yes. Dockflow automatically detects and suppresses low-quality data through a combination of anomaly detection, timestamp validation, and source ranking. For instance, if two identical milestones are reported with different times or from different carriers, Dockflow flags the conflict and isolates the most credible input. The system also recognizes out-of-sequence events, such as a discharge scan arriving before vessel departure, and filters them out before they reach the user. This ensures you operate on accurate, conflict-free data at all times.

How does Dockflow ensure accuracy and completeness of logistics data?

Each event in Dockflow is validated across three key vectors: source authenticity, timing integrity, and contextual alignment. Accuracy is enforced by triangulating data from satellite, terminal, and carrier feeds. Completeness is achieved by mapping full container journeys from booking to delivery, including intermediary steps like transshipments or port handovers. Every milestone is time stamped, verified, and indexed into a historical timeline. The result is a continuously reconciled data layer that supports audits, forecasting, and compliance without the gaps or inconsistencies seen in traditional systems.

Why is data quality important for supply chain decision-making?

Data quality is not a technical detail. It directly affects timing, coordination, cost, and customer satisfaction. Poor data leads to missed handoffs, inaccurate ETAs, surprise delays, and overreliance on email and manual follow-up.

Dockflow ensures that every decision, whether rerouting a container, scheduling a warehouse slot, or informing a consignee, is made with real time, trustworthy data. This reduces reaction time, increases delivery reliability, and minimizes the risk of penalties, chargebacks, or downstream disruptions.

How reliable is Dockflow’s data for emissions tracking and compliance reporting?

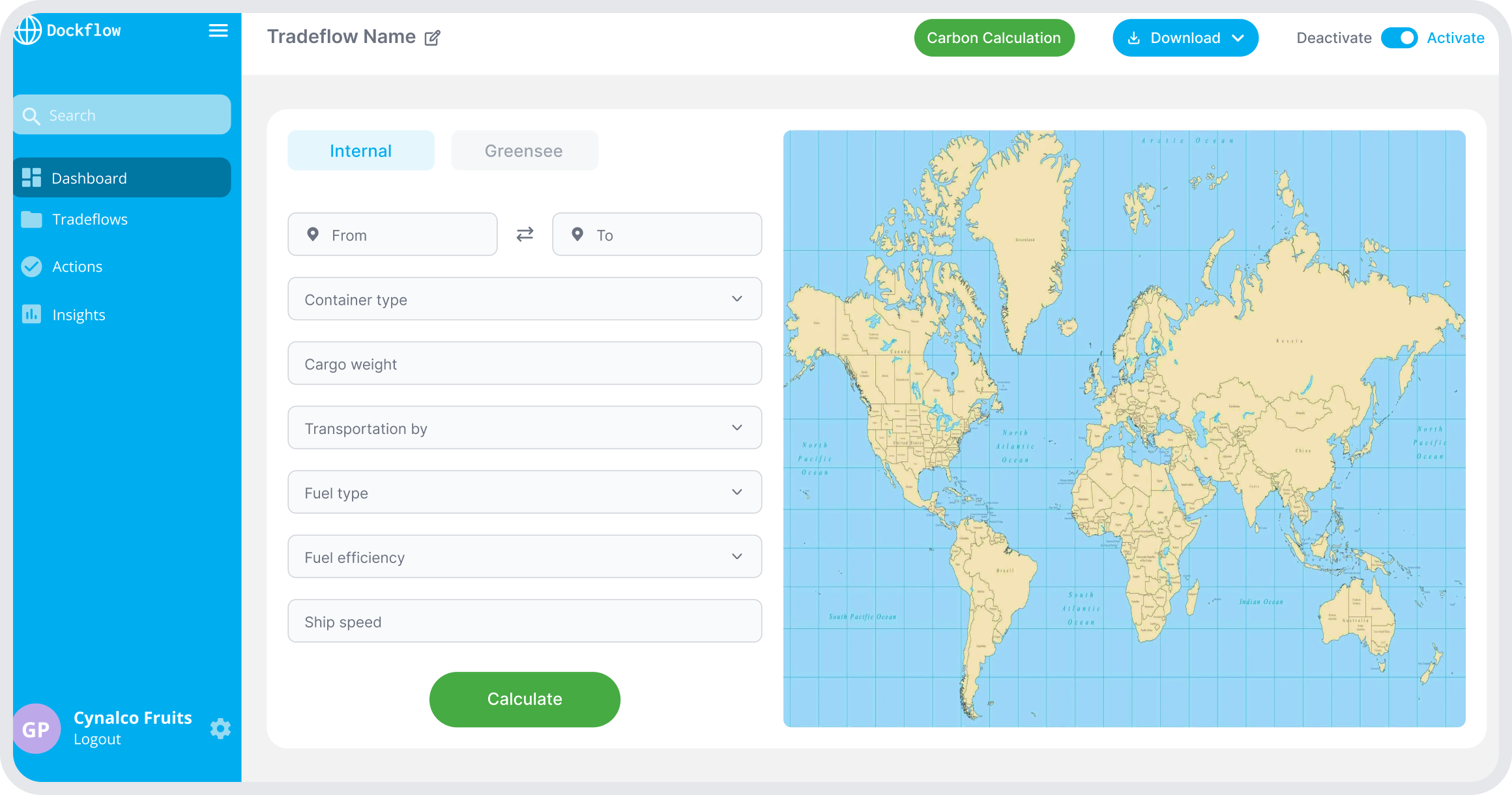

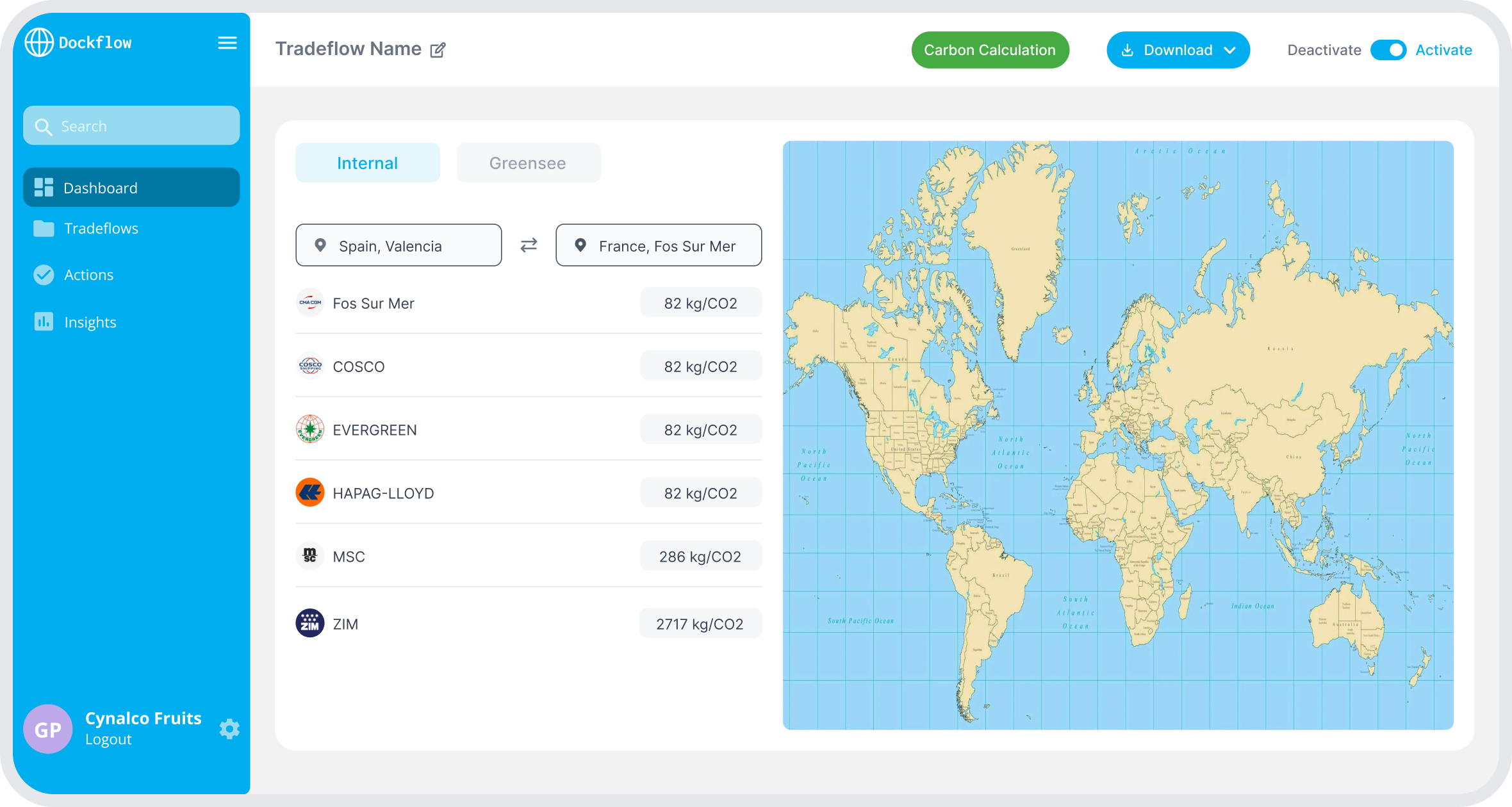

Dockflow’s emissions engine, RealCalc®, delivers unmatched accuracy by combining operational data with proprietary emissions algorithms built on the GLEC framework. Unlike tools that rely on averages or static route assumptions, RealCalc® uses live vessel behavior, actual fuel consumption proxies, and port conditions to calculate CO₂ emissions at a shipment-specific level.

This level of fidelity supports regulatory compliance with CSRD and other ESG frameworks, while enabling logistics teams to measure impact at the lane, customer, or product level.

How does Dockflow help reduce the risk of delays caused by bad data?

Bad data often leads to delayed handovers, incorrect customs filings, missed appointment slots, and uninformed stakeholders. Dockflow eliminates this risk by preventing flawed data from reaching critical workflows.

For example, if a departure milestone is missed due to a system error, Dockflow can detect the inconsistency using satellite vessel tracking and inject the missing event. This keeps supply chain plans aligned with reality and allows proactive interventions when exceptions occur.

Can Dockflow integrate with AIS, IoT sensors, and terminal systems for data quality?

Yes. Dockflow natively integrates AIS for vessel tracking, real time IoT sensors for temperature and humidity data, and port systems for terminal-level event capture.

These integrations power end-to-end data visibility from ocean leg to container yard. In sensitive cargo scenarios, such as pharmaceuticals or chemicals, this means operators can track environmental conditions alongside physical movements with the same level of reliability and traceability.

How does Dockflow help reduce the risk of delays caused by bad data?

Dockflow acts as a shared source of truth for all involved parties—forwarders, consignees, customs brokers, warehouses, and carriers. By ensuring that every partner sees the same validated data, Dockflow eliminates conflicting updates, repeated status checks, and reactive firefighting. Permissions-based access in the customer portal allows each stakeholder to receive tailored views of relevant milestones, documents, and condition updates, improving alignment and accountability without increasing operational overhead.