Supply chain visibility software is essential for logistics businesses to manage the complexities of modern supply chains. Such software integrates technologies like machine learning and GPS tracking to provide real-time insights. This enables companies to track shipments, optimize inventory, and enhance communication across their supply chain network.

With global disruptions and rising consumer expectations, companies that invest in real-time supply chain visibility solutions gain a competitive edge.

This guide explores how supply chain visibility software works, its benefits, and the best practices for implementation. We’ll also seize the chance to discuss how Dockflow is the leading choice for businesses looking to optimize their maritime supply chain performance.

In a Nutshell, What is Supply Chain Visibility?

Defining Supply Chain Visibility

Supply chain visibility refers to the ability to track shipments, monitor inventory levels, and gain insights into transportation visibility across logistics operations. By leveraging real-time data, AI-powered analytics, and cloud-based visibility platforms, businesses can gain end-to-end oversight of their supply chain management processes.

Unlike supply chain transparency, which focuses on ethical sourcing and compliance, supply chain visibility is about operational efficiency. It enables companies to respond proactively to delays, disruptions, and inventory shortages by leveraging real-time insights to improve decision-making.

How Supply Chain Visibility Works

Achieving full real-time supply chain visibility depends on three core components.

First, it all starts with data. IoT sensors, GPS ELD tracking, and telematics networks collect location, temperature, and status updates for shipments. This data is crucial for providing end-to-end visibility into freight movement and supply chain performance.

The second component is turning data into action. AI-driven analytics process real-time data, providing predictive insights into potential delays, arrival times, and carrier reliability. This enables businesses to make proactive decisions, ensuring operational efficiency and improved customer service.

The third component is platforms that make visibility easy. Real-time transportation visibility platforms (RTTVP) centralize shipment data, providing actionable insights and proactive alerts. These platforms integrate with existing supply chain management systems, ensuring seamless communication between logistics teams, carriers, and customers.

What is Supply Chain Visibility Software?

Supply Chain Visibility Software Explained

Supply chain visibility software connects carriers, freight forwarders, and shippers to enable seamless real-time supply chain tracking. It provides centralized real-time data on shipments, inventory levels, and transit statuses. It helps businesses optimize their logistics operations.

This allows for proactive management of exceptions, identify supply chain bottlenecks, and implement strategies that improve on-time delivery rates.

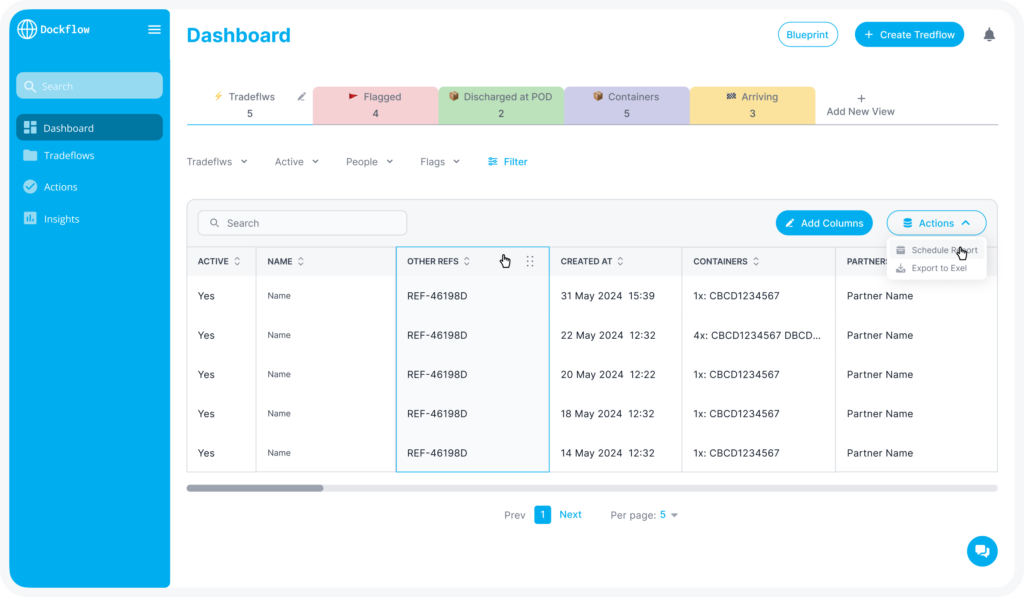

Dockflow is an AI-powered supply chain visibility software specializing in maritime logistics. It offers real-time transportation visibility and automated shipment tracking. The platform integrates with multiple data sources, including GPS tracking, IoT devices, and transport management systems. Dockflow ensures a holistic view of supply chain operations and a lot more.

Book a free demo now to see Dockflow in action with your own data!

Features of Supply Chain Visibility Solutions

A comprehensive supply chain visibility platform offers several features that drive efficiency and improve supply chain performance. Real-time shipment tracking across ocean, air, rail, and trucking networks allows companies to monitor freight movements and predict potential delays.

Inventory visibility ensures stock movement across warehouses, terminals, and ports, minimizing storage inefficiencies and ensuring goods reach their destinations on time.

Predictive analytics uses AI and machine learning to forecast and optimize logistics. Automated exception management proactively resolves supply chain issues, while shared visibility platforms enable real-time data sharing and coordination between stakeholders.

Why is Supply Chain Visibility Important?

As global trade complexities increase, businesses need real-time transportation visibility to navigate disruptions and rising consumer expectations.

Supply chains are no longer linear; they are vast, interconnected networks that require end-to-end oversight. Supply chain visibility software eliminates data silos, enabling proactive supply chain management through real-time data tracking.

Companies with enhanced visibility can mitigate risks, optimize inventory levels, and ensure shipments arrive on time, meeting customer service expectations.

Benefits of Supply Chain Visibility Software

Reduce Operating Costs

Supply chain visibility software plays a critical role in reducing operational costs. It optimizes freight movement and prevents unnecessary expenses such as demurrage, detention, and warehousing fees.

Without visibility, shipments often face unexpected delays at ports, warehouses, or distribution centers. This leads to increased storage and handling costs.

Automate Tracking Tasks

Manual tracking processes, including phone calls, emails, and status requests, slow down operations and increase administrative costs. Supply chain visibility software automates these tasks by providing real-time data on shipment statuses, estimated arrival times, and any potential disruptions.

Dockflow also supports automated alerts to help logistics teams respond quickly to transportation visibility issues. This ensures that all stakeholders remain informed without the need for continuous manual intervention.

This improves efficiency, eliminates redundant tasks, and enables teams to focus on strategic logistics planning rather than day-to-day tracking operations.

Improve On-Time Delivery

Ensuring on-time delivery is essential for maintaining customer satisfaction and avoiding contract penalties. Real-time supply chain visibility solutions provide accurate ETA predictions, helping logistics teams anticipate and mitigate potential delays.

By leveraging machine learning algorithms and GPS ELD tracking, companies can monitor real-time movements and reroute shipments if necessary to ensure on-time, in-full (OTIF) deliveries.

Improved delivery accuracy enhances overall supply chain performance, strengthens relationships with customers, and minimizes disruptions caused by unforeseen delays.

Centralize Communications Across Your Supply Chain

Supply chains involve multiple stakeholders, including shippers, carriers, freight forwarders, and warehouse operators. Without a centralized communication system, information silos can create inefficiencies, delays, and misaligned logistics strategies.

Supply chain visibility platforms connect all supply chain partners on a single, real-time data-sharing platform, allowing seamless coordination. With shared access to shipment updates, route optimizations, and exception management tools, all parties can work together more effectively to reduce bottlenecks and streamline operations.

This ensures that the entire supply chain remains synchronized, improving transportation visibility and logistics efficiency.

Deliver Superior Customer Service

Modern consumers and businesses expect complete transparency in their shipments. Supply chain visibility software provides real-time tracking updates, enabling companies to offer superior customer service by keeping end clients informed about their delivery statuses.

Key Supply Chain Visibility Metrics & KPIs

Measuring Success with Visibility Software

To maximize the benefits of supply chain visibility software, businesses must track key performance indicators (KPIs) that measure efficiency, sustainability, and delivery performance.

One of the most critical KPIs is OTIF (On-Time, In-Full) delivery performance. This metric tracks whether shipments arrive at their destination at the scheduled time and with the correct quantity of goods.

High OTIF rates indicate an optimized supply chain, while lower rates suggest inefficiencies such as transportation delays, poor inventory management, or carrier issues.

Another important metric is lead time reductions from real-time insights. By leveraging real-time transportation visibility and predictive analytics, logistics businesses can significantly reduce order fulfillment times and optimize logistics operations. Shorter lead times improve supply chain agility, helping companies respond faster to demand fluctuations and disruptions.

Lastly, carbon footprint monitoring is becoming an essential KPI for sustainability-driven logistics. With increasing pressure to reduce CO₂ emissions, businesses must measure their environmental impact using supply chain visibility platforms.

This KPI ensures that companies align with sustainability goals, comply with ESG regulations, and enhance their brand’s commitment to eco-friendly logistics practices.

Visibility Platform KPIs – You Can’t Fix What You Can’t See

Without real-time data tracking, businesses lack visibility into supply chain inefficiencies. Shipment exceptions resolved per day is a crucial KPI that tracks how quickly logistics teams identify and address disruptions, such as delays, route changes, or missing shipments. The faster exceptions are resolved, the more resilient and proactive the supply chain becomes.

Average delay time per shipment is another critical metric, providing insights into recurring bottlenecks and inefficiencies. Whether delays are caused by port congestion, customs clearance issues, or carrier delays, this KPI helps companies take corrective actions to minimize disruptions and improve customer service.

Lastly, carrier reliability tracking ensures that logistics teams monitor on-time performance, responsiveness, and service consistency of their shipping partners. A data-driven evaluation of carrier performance allows businesses to work with the most reliable freight providers, ensuring optimized transportation visibility and improved supply chain efficiency.

Supply Chain Visibility Software vs. Traditional Transportation Management System

How is a Real-Time Transportation Visibility Platform Different from a TMS?

A Transportation Management System (TMS) is designed primarily to optimize freight booking, manage carrier relationships, and control logistics costs. It streamlines order management, route planning, and freight invoicing. It is a crucial tool for logistics teams.

However, traditional TMS platforms lack real-time visibility, leaving supply chains vulnerable to disruptions, inefficiencies, and unpredictable delays.

In contrast, a Real-Time Transportation Visibility Platform (RTTVP) focuses on live tracking, predictive analytics, and automated exception management. By integrating real-time data from IoT sensors, GPS tracking, and telematics networks, RTTVPs provide continuous supply chain oversight.

These platforms enable companies to anticipate arrival times, detect route deviations, and proactively manage delays. It reduces operational risks and improves customer service.

Modern supply chains require both TMS and visibility software for full operational efficiency. While TMS platforms manage freight transactions and cost control, RTTVPs provide real-time transportation visibility. This allows companies to track shipments, optimize supply chain performance, and respond to disruptions in real-time.

Integrating both systems allows businesses to achieve a seamless, end-to-end logistics strategy. This results in improved efficiency, better risk management, and enhanced visibility across their entire network.

Best Practices for Implementing Supply Chain Visibility Software

Ensure Effective Adoption of Visibility Software

Implementing supply chain visibility software is a seamless process that does not require a dedicated team to manage data or oversee tracking manually. Modern visibility platforms, like Dockflow, are designed to automate real-time tracking, data collection, and predictive insights. They eliminate the need for constant monitoring by in-house teams.

Instead, logistics businesses should focus on training key personnel to effectively use the software and leverage its full potential.

Users should be trained to interpret insights, respond to alerts, and utilize predictive analytics to optimize logistics decisions.

The software provider typically manages data integrity, software updates, and integration with existing supply chain systems. This allows logistics teams to focus on strategic operations rather than manual tracking.

Proper training ensures businesses can maximize the benefits of real-time transportation visibility while minimizing disruptions and inefficiencies.

Choose the Right Visibility Platform for Your Needs

Selecting the right supply chain visibility software is critical to ensuring long-term success. Businesses must evaluate platforms based on scalability, integration capabilities, and AI-powered insights. Scalability ensures that the solution can grow alongside business operations, accommodating multi-modal transportation tracking across air, ocean, rail, and truck.

Integration with existing transportation management systems (TMS), enterprise resource planning (ERP) platforms, and warehouse management systems (WMS) is essential for seamless data exchange and operational synchronization.

Additionally, AI-powered predictive analytics and automated exception management enhance decision-making, allowing businesses to anticipate delays, optimize routes, and mitigate risks before they escalate.

Automate Manual Processes for Greater Efficiency

Supply chain visibility software eliminates inefficiencies by automating real-time shipment tracking, ETA updates, and inventory movement notifications. Companies can replace outdated communication methods with automated workflows, significantly improving supply chain efficiency and responsiveness.

By integrating real-time data feeds from multiple sources, businesses ensure that all stakeholders receive accurate, up-to-the-minute insights on shipment statuses, warehouse inventory levels, and transportation schedules.

Foster Collaboration Across the Supply Chain

Supply chain visibility is most effective when all stakeholders (shippers, carriers, freight forwarders, warehouse managers, and logistics coordinators) operate on a shared visibility platform.

When organizations foster collaboration between partners, they enhance transparency, reduce friction in supply chain communication, and improve coordination across multi-party logistics networks. Cloud-based transportation visibility platforms enable stakeholders to share real-time data, predictive insights, and exception alerts. They ensure that supply chain teams can respond proactively to disruptions.

Aligning suppliers, carriers, and warehouse operators on a single visibility platform creates a more resilient, agile supply chain. This reduces operational risks and improves customer service.

The Future of Supply Chain Visibility Software

Trends in Supply Chain Visibility Technology

AI-driven predictive logistics uses real-time data to anticipate delays, optimize routes, and improve decision-making. This allows businesses to manage risks, reduce lead times, and enhance efficiency.

Additionally, blockchain and IoT (Internet of Things) are playing an increasingly significant role in enhancing supply chain transparency.

Blockchain technology enables secure, tamper-proof data sharing among stakeholders. It ensures that shipment records, inventory movements, and transaction details are immutable and easily verifiable.

IoT devices, such as smart sensors and GPS tracking systems, provide real-time transportation visibility. It helps businesses monitor temperature-sensitive goods, track shipment progress, and improve warehouse efficiency.

Eliminating Supply Chain Friction with Real-Time Data

Data fragmentation is a major challenge in supply chain management, causing inefficiencies and delayed decision-making. Breaking down data silos and integrating real-time data enables companies to detect disruptions sooner, reroute shipments proactively, and improve supplier collaboration.

AI-powered insights and machine learning algorithms can identify bottlenecks, optimize workflows, and enhance supply chain performance.

Digital freight networks are connecting carriers, shippers, and freight forwarders on a unified platform for real-time collaboration, dynamic pricing, and automated load matching. This transformation of global logistics results in greater efficiency and cost savings.

Businesses that embrace real-time data, automation, and predictive analytics will stay ahead of competition and continuously improve efficiency and reliability.

Start Enhancing Your Supply Chain Today with Dockflow’s Visibility Software

The need for supply chain visibility software has never been greater. Businesses that fail to integrate real-time tracking, predictive analytics, and AI-powered automation into their logistics operations risk inefficiencies, increased costs, and reduced competitiveness.

By leveraging Dockflow’s cutting-edge supply chain visibility platform, companies can:

- Enhance supply chain performance

- Optimize freight operations

- Improve customer satisfaction

- Ensure compliance with CSRD

- And a lot more!

Now is the time to transform your supply chain operations. Book a free demo with Dockflow today and experience how real-time supply chain visibility software can elevate your logistics strategy and drive long-term success.